What are virgin plastic beads? This is a special type of plastic resin that is gradually being commonly used in many fields, including the production of stretch film, food wrap or product straps. So what outstanding characteristics does this type of plastic have, is it safe to use or not? Join FASMPO to find out the answer in this article!

What are virgin plastics?

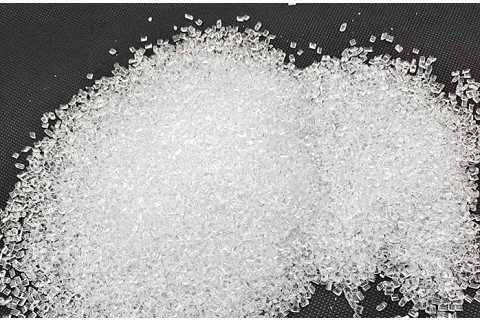

Primary plastic beads also known as virgin plastic, are plastic created from the fractional distillation of petroleum. They are also called new plastics or virgin plastics.

Primary plastic beads are usually clear white. Therefore, when producing to diversify products, we can add colorants to create products with different colors. Primary plastic pellets are highly elastic, soft, flexible, and have good bearing capacity, often used in manufacturing industries that require high safety such as: packaging production, food packaging,... In addition, The production of virgin plastic beads is highly appreciated because they are non-toxic and very safe for human health. Therefore it is highly applied in the food field

FASMPO-VIRGIN PLASTIC

Popular types of virgin plastic beads:

Currently, there are many popular types of virgin plastic resins on the market such as PE, PP, PET, etc. Each type will have its own characteristics and be used to produce different products to meet the needs of customers. user specific. Specifically, some common types of virgin plastic beads include:

PP plastic is the abbreviation for Polypropylene, a hard thermoplastic produced from Monomer Propylene (or Propylene). PP virgin plastic beads have the following characteristics:

- Primary PP plastic beads are colorless, odorless, tasteless and non-toxic.

- PP plastic has transparent color and glossy surface for high and clear printing ability.

- It is highly durable, quite hard and inelastic.

- Able to withstand good temperatures (over 100 degrees Celsius)

- Primary PP plastic pellets have a relatively light density

- Good electrical properties, not affected by humidity

PP plastic is safe and friendly so it is commonly used in daily life. Specifically, PP virgin plastic beads are used in the production of materials and components, used in medicine, food packaging, and other common products.

ABS plastic's full name is Acrylonitrile Butadiene Styrene, has the characteristics of being hard, dense but not brittle, insulating, waterproof, resistant to temperature and chemicals so it does not deform the product during use. Below are some characteristics of virgin ABS plastic beads:

- High hardness, good impact resistance, difficult to get scratched when there is a collision

- High durability under continuous heat pressure for long periods of time.

- Has good electrical and water resistance

- Melting temperature of ABS plastic: 190-220°C.

ABS plastic often used in many fields such as electronics, household appliances, automobile industry, motorbikes, packaging, construction materials.

PE plastic has variations such as: HDPE, LDPE, LLDPE. In particular, LLDPE plastic is used to produce stretch film, food wrap, etc. PE plastic has variations such as: HDPE, LDPE, LLDPE. In particular, LLDPE plastic is used to produce stretch film, food wrap, etc

- Long lifespan, sometimes approaching 50 years

- High connectivity should have high tightness, no interruptions or leaks.

- Resists pressure and impact well.

- Resists corrosion caused by chemicals.

- Hot temperature of PE virgin plastic beads: 170-200°C

- Specific gravity of virgin plastic PE: 0.91-0.97g/cm3

- PE plastic shrinkage: 2〜6%

- The appropriate temperature when pressing PE plastic is 40-60°C

Refer to products made from PE plastic beads at the link below.

Products: https://fasmpo.com/packaging-products

Contact to FASMPO for good prices: https://fasmpo.com/information/contact